Product Categories

Quality

Nothing But The Best

Secure

100% Secure Payments

Warranty

All Products Guaranteed

Support

We Know Radiators.

Best Selling

-

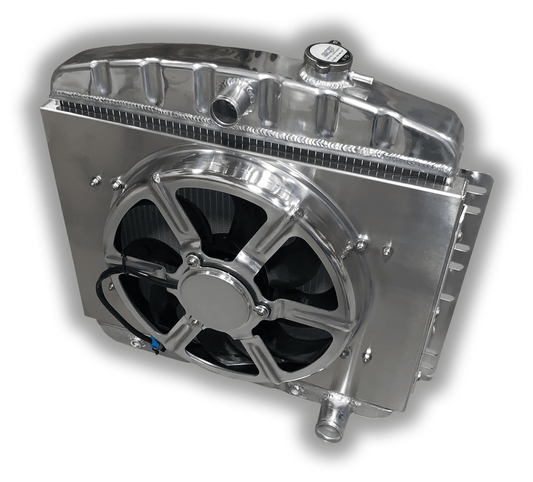

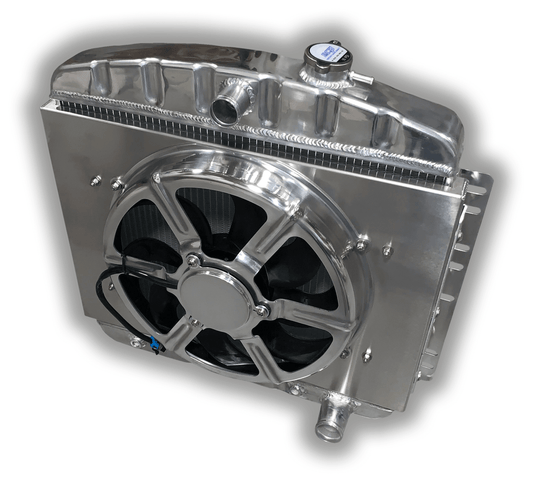

1948 - 1954 Chevy Radiator - 16" HPX 3300 CFM Fan + Shroud

Regular price $677.00 USDRegular priceUnit price per$597.00 USDSale price $677.00 USD -

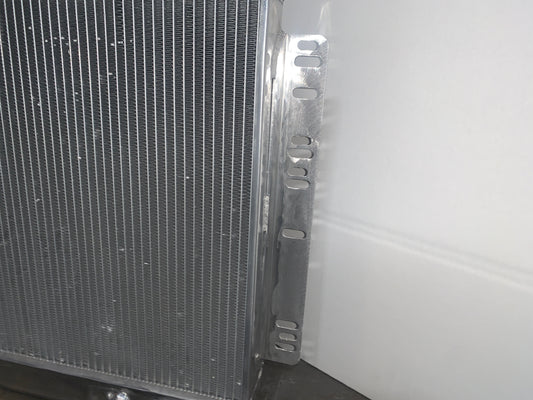

1948 - 1954 Chevy Radiator V8 SBC/BBC

Regular price $347.00 USDRegular priceUnit price per$297.00 USDSale price $347.00 USD -

1948 - 1954 Chevy Radiator V8 SBC/BBC

Regular price $210.00 USDRegular priceUnit price per$297.00 USDSale price $210.00 USDSold out -

1948 - 1954 Chevy Truck Aluminum Radiator

Regular price $347.00 USDRegular priceUnit price per$297.00 USDSale price $347.00 USD

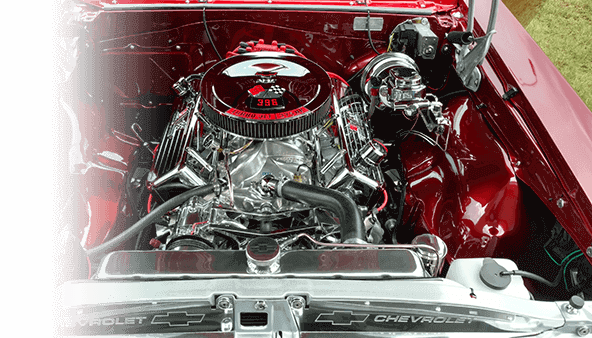

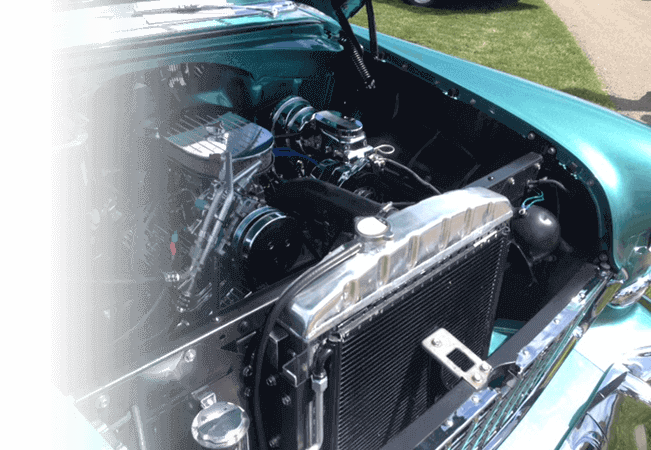

We do one thing: Radiators. That’s it!

A radiator is something that you only want to purchase once. With the advent of the interweb, it’s easy for anyone to position themselves as an 'expert'. The guy who you’re e-mailing with might have been pulling motors out of wrecks at the junkyard last week.

Or even worse, you’ll find snake oil sales men peddling three row radiators. You’ll want ot avoid these like the plauge. A three aluminum radiators will actually create two problems for you when you only started with one problem: they will lighten your wallet AND they won’t cool your car.

We are engineers that know cooling in and out. That’s why we can offer a cooling guarantee and a lifetime warranty. We know our products will cool your car and we know they last for as long as you own your car.